The bulk of the industrial region along the Mahoning River Valley extends for 25 miles, through Youngstown, from Warren at the north, to Lowellville at the south.

Dozens of former and current steel operations line the river.

The northernmost plant is the former Copperweld Steel plant, which went bankrupt in 1993.

It is now owned by Warren Steel Holdings, and produces around 400,000 tons of steel a year, from scrap.

South of Warren is a plant that is owned by RG Steel, a company that declared bankruptcy in 2012.

Though still producing, it's future is in flux.

The plant has three components: the melt shop, the mill, and a coke plant, owned separately by ArcelorMittal.

The melt shop has the capacity to produce 1.9 million tons of raw steel per year.

The mill is diversified and provides custom steel products, for the time being.

The Defense Logistics Agency operates a large storage facility at the southern end of the plant.

Nearby, RMI Titanium in Niles machines specialty metals, but makes no raw steel.

The remains of the U.S. Steel plant at McDonald are now mostly used for storage of old rail equipment.

The rest of the plant, built during World War I, has been torn down after closing in 1980.

The largest steel business along the Mahoning River today is the V&M Star Steel Company.

The plant occupies parts of the old U.S. Steel Ohio Works site, and is expanding to supply pipe for the oil and gas industry.

V&M, otherwise known as Vallourec & Mannesman, based in Houston, is partnering with Sumitomo Steel on the project.

The plant makes 550,000 tons of steel a year, though that will expand when the $650 million pipe mill is finished.

The southern part of the plant is the site of the former Briar Hill Works of the Youngstown Sheet and Tube Company.

For more than half a century, Youngstown Sheet and Tube was the dominant company in the valley.

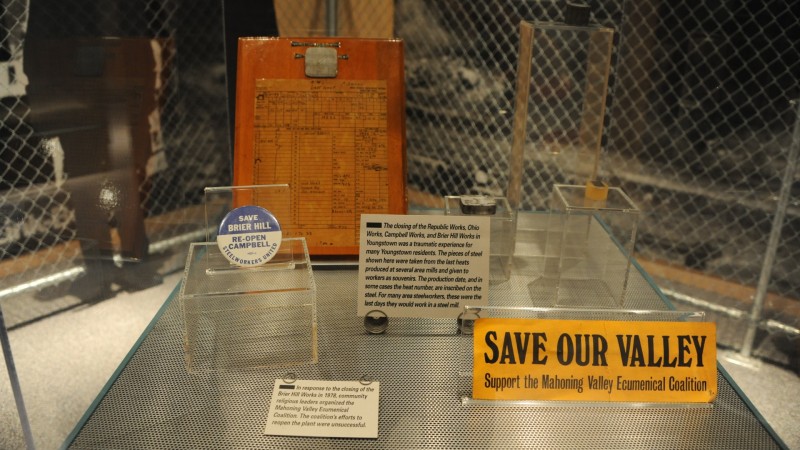

The industrial history of the valley is preserved and displayed in the Youngstown Historical Center of Industry & Labor, operated by the Ohio Historical Society.

Located in the heart of Youngstown, the museum and archives are in a Michael Graves-designed building erected in the 1980s.

The exhibit was installed in the 1980s and has not been significantly altered since.

It tells the story of local labor and industry, which was dominated by steel.

Of the few public exhibits about the steel industry in the nation, it is the largest.

The former Republic Steel Youngstown Works site covered most of the river bank south of downtown Youngstown.

Republic Iron and Steel was founded in Youngstown in 1899, and became the third largest steel company in the nation, after U.S. Steel and Bethlehem Steel.

With the decline in the industry, it became part of LTV Steel in 1984. LTV Steel filed for bankruptcy in 2001.

South of Republic was the Campbell Works of Youngstown Sheet and Tube.

The Campbell Works were extensive, with 4 blast furnaces, 12 open hearth furnaces, and 381 coke ovens.

Mostly gone now, the plant extended to the dam at the southern end of the valley.

The Wheatland Tube company operated in a portion of the former plant site, and built new sheds too.

It has been purchased by NLMK, a Russian steel company.

The old headquarters for Youngtown Sheet and Tube lies derelict above the former Campbell Works Site.

The industrial area south of downtown Cleveland, along the Cuyahoga River, is as dense as it is notorious.

It is dominated by the Cleveland Works steel plant, an assemblage of facilities known for years as LTV Steel.

In 2002, LTV was bought by ISG, which was bought by Mittal Steel in 2005, and merged with Arcelor in 2006, to become ArcelorMittal, the world’s largest steel company.

At the northern end is the #2 basic oxygen furnace, and the #1 continuous caster plant.

Blast furnace 5 and 6 are located to the south.

West of that is the Direct Hot Charge Complex, with its furnace, caster, and hot strip mill.

South of that is a cluster of sheds containing finishing, coating, and hot strip mills.

Landfill and waste product management dominates the southeast end of the complex.

The total output for the complex is almost 4 million tons of raw steel per year, the largest in the state.

Other metal industries around the plant include the Charter Steel Plant, which produces around 500,000 tons per year.

Alcoa’s Cleveland Works is an aluminum plant once known as Air Force Plant 47.

20 miles west of Cleveland is an old integrated steel plant in Lorain, active since 1895.

Republic Steel operates most of the plant, which can produce up to 840,000 tons of steel per year.

Republic, now owned by a Mexican company, makes mostly bar steel for things like truck axles.

The eastern end of the plant is owned by U.S. Steel, which just added a new $100 million pipe mill.

Like some other plants, demand for pipe for gas extraction is spurring the steel industry.

Republic Steel is based in Canton, Ohio, 50 miles south of Cleveland.

The bloom cast facility in Canton can produce nearly 1.4 million tons of steel a year.

Timken Steel has been based in Canton Ohio since 1901, primarily making bearings for the auto industry. The company’s two plants are being expanded to supply steel for the energy industry.